We are currently working with City University of Hong Kong (CityU) to develop a Smart Geotechnical Monitoring Architecture (SGMA), Hong Kong’s first 24-hour AI technology system to gather and analyze construction site’s geospatial data.

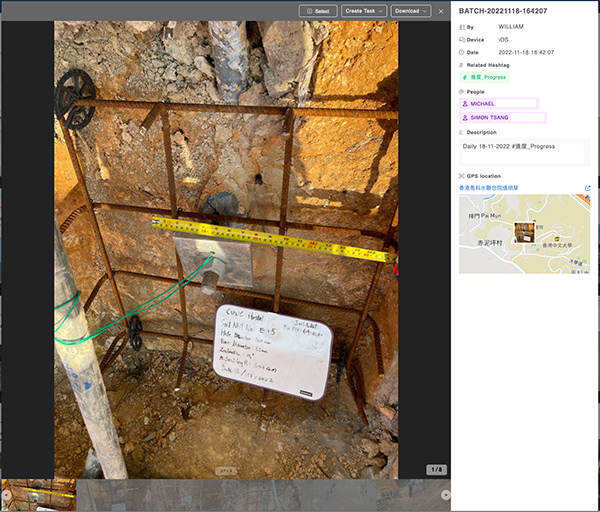

The SGMA system consists of 3 types of sensors: Water level sensor, Tilt Sensor (Wall Mount) and Inclinometer. These sensors are applicable for building sites and construction sites. With the use of cloud technology, the automation of SGMA can provide real-time monitoring of site conditions.

Trials have already been carried out in different construction sites and the application of SGMA will hugely reduce data processing time, manpower and cost in the future.